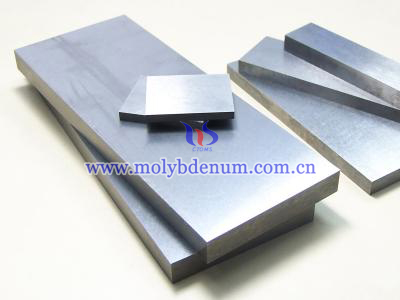

Molybdenum Sheet as Parts of Machine

Molybdenum sheet in vacuum furnace as connecting pieces

Reasons to choose molybdenum as material

Almost all high-temperature vacuum furnaces are electrically resistance heated. Heating elements may be constructed from metal or graphite in a variety of styles. The choice of a heating-element material depends largely on operating temperature. For higher-temperature general heat-treating applications such as hardening or brazing, molybdenum is one of the most popular element materials.

Reasons to choose molybdenum sheet

For many years, molybdenum elements were used almost exclusively in vacuum furnaces for general heat-treating and brazing applications. Consequently, molybdenum sheet is a good choice for customers to use in vacuum furnaces to meet the requirements of corrosion resistance and obtain the objection of longer used products. At the same time, the most widely used molybdenum sheet design incorporates lightweight, durable and easy to work with. As a result, molybdenum sheet is a better choice than other materials in vacuum furnaces.